ASPUR airsorb2, airsorb2fd

Storage filter ASPUR airsorb2

Storage filters of the airsorb2 assembly are used in manufacturing plants to extract and safely separate gases*, fumes, odors*, proportional dusts (airsorb2 model) at processing machines. In addition, these units can also be used to extract aerosols and oil mists (airsorb2fd model). Due to the large dimensioned filter systems, long filter service lives result.

*) only with activated carbon filter

The puristic and modern design of the ASPUR devices is also reflected in this device group. During development, care has been taken to ensure that access to all areas is as extensive as possible. All filters can therefore be replaced within a very short time. G4 coarse filters in a plastic frame and retaining plate and aluminum mesh filters are coarse pre-separators and spark arrestors, respectively. Both filters can be easily removed and reinserted.

The main filter system consists of an F9 filter (airsorb2 model) or fogdrain filter (airsorb2fd model) and H14 filter or H14 filter with integrated coalescence filter and can be pulled out very easily from its final position. The drawer system developed for this purpose is protected as a utility model. The filters can be completely extended and removed or replaced from the holder. After insertion of the filter pack, they are automatically brought into the end position and sealed.

Thanks to the modular design, a wide variety of prefilters and main filters such as HEPA filters, activated carbon filters, demister filters, G4 filters, F9 filters, and Fogdrain filters can be used or combined. The intake space below the pre-filters is dimensioned in such a way that a filter bag or a pre-filter box can be inserted as required.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High-quality filter system with pull-out for filter change without tools |

| Integrated H14 filter |

| Integrated multi-stage filter system G4, aluminum knitted filter, ISO 85 ePM1, filter bag (polyester fleece), HEPA H14 filter |

| Alternative coalescence filter |

| Large access doors (service friendly) |

| EC extraction blowers and fans |

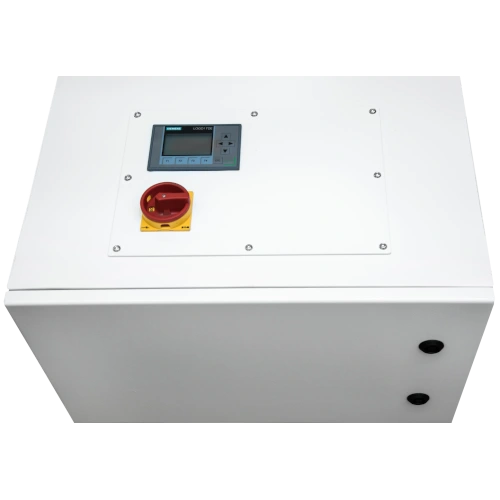

| Integrated Siemens LOGO control with display and Modbus TCP connection |

| Powder coating RAL9016 white |

| Industrial swivel castors with stopper, conductive |

Order now our storage filter airsorb2 for your workplace!

Optional device features |

|---|

| Gas-Ex Z2 and Z1 |

| Dust-Ex Z22 and Z21 |

| Completely available in stainless steel design |

| All RAL colors in powder coating |

| Activated carbon filersystem |

| Filter bag, filter box |

Order now our storage filter airsorb2 for your workplaces!

Areas of application | |

|---|---|

| Processes | |

| Lasering, welding, cutting | |

| Filling, mixing | |

| Vaporizing | |

| Packaging | |

| Bonding, coating | |

| Materials |

| Fume, smoke |

| Gases, odors |

| Dust, fine particles |

| Fibers, fabrics |

Order now our storage filter airsorb2 for your workplaces!

Technical data

airsorb2 (smoke, dusts) and airsorb2fd (aerosols, oil mist)

| airsorb2 EC 1.1 for smoke, dusts |

airsorb2 EC 2.2 for smoke, dusts |

airsorb2 EC 1.4 for smoke, dusts |

airsorb2 EC 2.8 for smoke, dusts |

airsorb2fd EC 1.1 for aerosols, oil mist |

airsorb2fd EC 2.2 for aerosols, oil mist |

airsorb2fd EC 1.4 for aerosols, oil mist |

airsorb2fd EC 2.8 for aerosols, oil mist |

|

|---|---|---|---|---|---|---|---|---|

| Item no. | 9010138 | 9010139 | 9010129 | 9010140 | 9010141 | 9010142 | 9010143 | 9010133 |

| Air volume flow | max. 350 m³/h | max. 700 m³/h | max. 940 m³/h | max. 1880 m³/h | max. 350 m³/h | max. 700 m³/h | max. 940 m³/h | max. 1880 m³/h |

| Negative pressure | max. 10000 PA | max. 10000 PA | max. 5000 PA | max. 5000 PA | max. 10000 PA | max. 10000 PA | max. 5000 PA | max. 5000 PA |

| Drive power | 1.1 kW | 2x 1.1 kW | 1.4 kW | 2x 1.4 kW | 1.1 kW | 2x 1.1 kW | 1.4 kW | 2x 1.4 kW |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | ||

| Voltage | 230 V | 230 V | 230 V | 230 V | 230 V | 230 V | 230 V | 230 V |

| Amps | max. 8.7 A | max. 2x 8.7 A | max. 12 A | max. 2x 12 A | max. 8.7 A | max. 2x 8.7 A | max. 12 A | max. 2x 12 A |

| Sound emission | 61 dB(A) | 63 db(A) | 63 dB(A) | 64 dB(A) | 61 dB(A) | 63 db(A) | 63 dB(A) | 64 dB(A) |

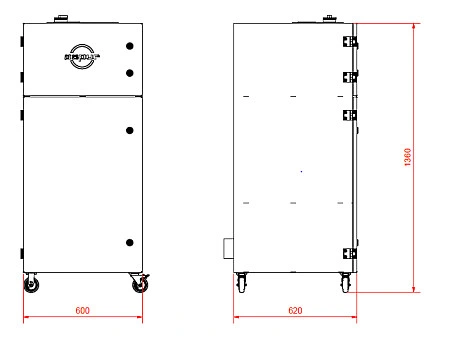

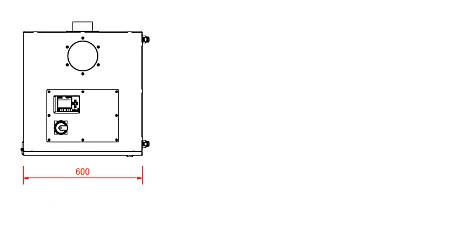

| Dimensions (l,w,h) | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm | 600x620x1350 mm |

| Intake (d) | 50 mm, 60 mm | 70 mm, 100 mm | 100 mm | 100 mm | 50 mm, 60 mm | 70 mm, 100 mm | 100 mm | 100 mm | Powder coating | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | HEPA H14 filter | yes | yes | yes | yes | yes | yes | yes | yes |

| Fogdrain filter¹ | no | no | no | no | yes | yes | yes | yes |

| Prefilter F9² | yes | yes | yes | yes | no | no | no | no |

| G4 filter | yes | yes | yes | yes | yes | yes | yes | yes |

| Metal mesh alu-filter | yes | yes | yes | yes | yes | yes | yes | |

| Controller³ | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® |

Right trimmed columns can be scrolled (wiped) to the left!

Optional features

| airsorb2 EC 1.1 for smoke, dusts |

airsorb2 EC 2.2 for smoke, dusts |

airsorb2 EC 1.4 for smoke, dusts |

airsorb2 EC 2.8 for smoke, dusts |

airsorb2fd EC 1.1 for aerosols, oil mist |

airsorb2fd EC 2.2 for aerosols, oil mist |

airsorb2fd EC 1.4 for aerosols, oil mist |

airsorb2fd EC 2.8 for aerosols, oil mist |

|

|---|---|---|---|---|---|---|---|---|

| Dust Ex-Zone 22 | yes | yes | yes | yes | no | no | no | no |

| Dust Ex-Zone 21 | no | no | no | no | no | no | no | no |

| Gas Ex-Zone 2 | no | no | no | no | no | no | no | no |

| Gas Ex-Zone 1 | no | no | no | no | no | no | no | no |

| Activated carbon filter | yes | yes | yes | yes | yes | yes | yes | yes |

| Demister filter | yes | yes | yes | yes | yes | yes | yes | yes |

| Stainless steel version | yes | yes | yes | yes | yes | yes | yes | yes |

| Filter bag class M | yes | yes | yes | yes | no | no | no | no |

| Filter box F9 prefilter | yes | yes | yes | yes | no | no | no | no |

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-MODULAR-DESIGN - Structure in modular assemblies, enables extensive variety of variants

- ASPUR-DOOR-SYSTEM - Large doors for barrier-free access

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to highly efficient sound insulation

- ASPUR-EASY-FILTER-CHANGE - Simple, tool-free filter change

Device features