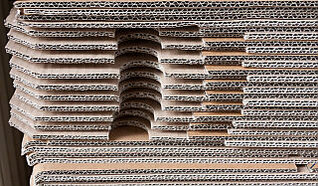

When materials are sawn, cut, welded, ground or polished, harmful dusts, chips, suspended matter and, when working with solvents, toxic fumes can be generated. We have the right dedusting, extraction and air cleaning solution for the various work processes and the emissions they produce.

Our extraction and cleaning systems have a modular structure, with optionally selectable filtering, discharge and disposal systems. For all process steps, we supply dedusting, extraction and air cleaning solutions tailored to your work processes. We will always find a suitable solution for you!

Select your working area from the process group images above and look for the right dedusting, extraction or air cleaning system in our product overview above. If you need advice, or something is still unclear, or you have some questions, just give us a call!Absauganlagen. Dank dem optionalen IFA-Prüfzeichen W3 oder einer ATEX-konformen Absauggerät-Ausführung ist selbst eine Absaugung besonders gefährdender Stoffe möglich.