ASPUR aero3eco

Deduster ASPUR aero3eco

The dust extractor aero3eco is our powerful mid-range model of the aero series and is used in the manufacturing industry to extract and safely separate dust, chips, smoke and gases*. The units are designed in terms of filtration and safety so that they can be used indoors and in potentially explosive** areas.

*) with opt. activated carbon filter **) with opt. fire und/or explosion protection components

Industrial centrifugal fans with backward curved impellers and Siemens IE3 motors of the latest generation provide both a low-noise and reliable drive. Together with the installed frequency converter, the motors can be variably adjusted to the desired outputs, either manually or automatically. These features ensure that only the power actually required is called up, thus reducing power consumption and loss of materials.

Large access doors installed on both sides, which extend over the entire height and width of the modules, allow the user quick and service-friendly access to all components.

In addition, all filter systems are designed to be changed without tools. The intake system with baffle plate, deflection and expansion area reduces the filter load and protects it from incoming particles.

Due to the modular design, HEPA filters, activated carbon filters, explosion and fire protection systems as well as various discharge systems can be added according to the customer's individual requirements and can be upgraded at a later date.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High quality filtersystem |

| Integrated H14 filter (optional) |

| Simple, fast, tool-free filter change (replacable pre-filter) |

| Large access doors on both sides (service-friendly) |

| IE3 centrifugal fans |

| Control cabinet with frequency converter, Modbus and display (user-friendly) |

Order now our dust extractor aero4eco for your workplace!

Optional device features |

|---|

| Gas-Ex Z2 and Z1 |

| Dust-Ex Z22 and Z21 |

| UL, CCC, GMP-compliant design |

| Stainless steel version |

| All RAL colors in powder coating |

| Activated carbon filter system |

| Fire protection equipment |

| Explosion protection equipment |

| HEPA H14 filter |

| Misc. discharge systems (rotary valve, big bag, double slider) |

Order now our dust extractor aero4eco for your workplace!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Drilling, lathing, milling |

| Filling, mixing |

| Packaging |

| Materials |

| Fume, smoke |

| Dust, fine particles |

Order now our dust extractor aero3eco for your workplace!

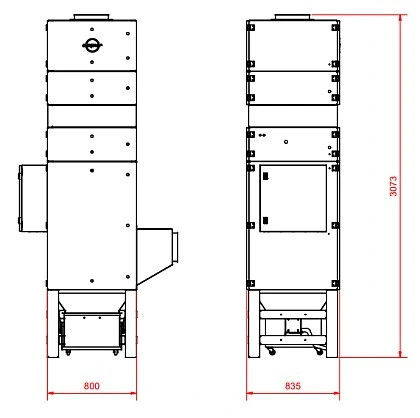

Technical data

| aero4eco D1.5 | aero4eco D2.2 | aero4eco D3 plugin | |

|---|---|---|---|

| Item no. | 9020165 | 9020167 | 9020168 |

| Air volume flow | max. 2300 m³/h | max. 3000 m³/h | max. 4000 m³/h |

| Negative pressure | max. 2300 PA | max. 2800 PA | max. 3500 PA |

| Drive power | 1.5 kW | 2.2 kW | 3 kW |

| Voltage | 400 V | 400 V | 400 V |

| Sound emission | 63 dB(A) | 63 db(A) | 63 dB(A) |

| Weigth | 520 kg | 530 kg | 530 kg |

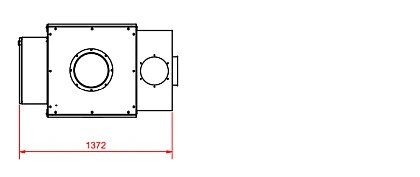

| Dimensions (l,w,h) | 800x800x2600 mm | 800x800x2600 mm | 800x800x2600 mm |

| Dimensions¹ (l,w,h) | 800x1370x3000 mm | 800x1370x3000 mm | 800x1370x3000 mm |

| Dimensions² (l,w,h) | 800x1370x3100 mm | 800x1370x3100 mm | 800x1370x3100 mm |

| Intake port (d) | 250 mm | 250 mm | 250 mm |

| Dust coll. container | 50 L | 50 L | 50 L |

| Powder coating | RAL9016 mat | RAL9016 mat | RAL9016 mat |

| Filter class | M | M | M |

| Filter surface | 30 m² | 30 m² | 30 m² |

| Filter surface load | 76 m³/m²/h | 100 m³/m²/h | 130 m³/m²/h |

| Filter cleaning³ | JetPulse | JetPulse | JetPulse |

| Controller | Siemens Logo® | Siemens Logo® | Siemens Logo® |

Right trimmed columns can be scrolled (wiped) to the left!

Optionals features

| aero4eco D1.5 | aero4eco D2.2 | aero4eco D3 plugin | |

|---|---|---|---|

| Endless bag system | yes | yes | yes |

| Hobbock container | yes | yes | yes |

| PE-Bag | yes | yes | yes |

| Rotary valve | yes | yes | yes |

| Slider | yes | yes | yes |

| ePTFE membr. filter | yes | yes | yes |

| HEPA filter class H14 | yes | yes | yes |

| Dust Ex-Zone 22/21 | yes | yes | yes |

| Gas Ex-Zone 2/1 | yes | yes | yes |

| Explosion protection* | yes | yes | yes |

| Fire protection* | yes | yes | yes |

| Activated carbon filter | yes | yes | yes |

| Stainless steel version | yes | yes | yes |

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-MODULAR-DESIGN - Structure in modular assemblies, enables extensive variety

- ASPUR-DUAL-DOOR-System - Accessible from two sides via large doors

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to highly efficient sound insulation

- ASPUR-EASY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR-Expansion-Extraction-System - Baffle plate, deflection and abrupt expansion of the intake process air, reduces the filter load and enables coarse particle separation

Device functions